Africa’s Largest Copper Smelter at Kamoa-Kakula Outputs First Batch of Copper Anode

On 2 January 2026, Ivanhoe Mines (TSX: IVN) announced the output of its first batch of #copper anode from its smelter at Kamoa-Kalula. The smelter is the largest in Africa with an annual capacity of 500,000 tonnes. The new smelter will surpass the other Lualaba Copper Smelter, which has an annual capacity of 120,000 tonnes of blister copper.

In 2025, Kamoa-Kakula produced 388,838 tonnes of copper concentrate, and in 2026, the production could reach 420,000 tonnes. Initially, the daily production of the smelter will average 500 tonnes of copper anode with a purity of 99.7%. During 2026, production will gradually ramp up to reach the full capacity of the plant.

Copper is classified as one of the #CriticalMinerals in high demand due to the buildout of Artificial Intelligence (AI) data centers and adoption of Electric Vehicles (EV). Indeed, An #EV needs three to four times more copper than a traditional internal combustion engine (ICE) vehicle. A single 1-GW #AI data center has between 50,000 to 65,000 tonnes of copper for power distribution, networking, and thermal dissipation.

“The first production of copper anodes from our world-class smelter is a defining moment for Kamoa-Kakula… This achievement is the culmination of a $1.1 billion investment, 18 million man-hours of disciplined execution, and an outstanding health and safety record that reflects the professionalism and commitment of everyone involved.”

Ivanhoe Mines Founder and Executive Co-Chair Robert Friedland

The smelter is powered by its own 60-MW solar farm, with battery storage. A UPS is on standby which can provide two hours of power in case of failure of the primary source. The site also has a 180-MW diesel generator, which can be put to use, if necessary. Most of the time, the smelter will operate from grid electricity, which is generated mostly from hydro power.

The Kamoa-Kakula already has a concentrator plant with an annual capacity of 600,000 tonnes of copper concentrate. The concentrate is then fed into the smelter to produce the copper anode. The smelter also outputs a slag which contains about 4% of copper, which can be reprocessed to achieve a recovery rate of 98.5%.

As a by-product, the smelter will also produce sulphuric acid, which can generate an extra stream of revenue. For 2026, the plant is forecasted to produce 700,000 tonnes of sulphuric acid.

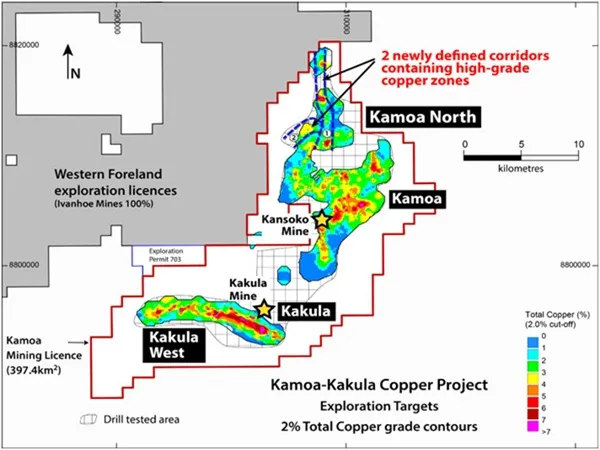

The Kamoa-Kakula Copper Complex is operated by Kamoa Copper SA, which is owned by Kamoa Holding (80%) and the DR Congo Government (20%). In turn, Kamoa Holding is basically a joint venture between Canada’s Ivanhoe Mines and China’s Zijin Mining. Each partner owns 49.5%, and the remaining 1% is held by Crystal River Global. Zijin Mining has also invested in Ivanhoe Mines, holding about 13% shareholding, which brings the Chinese interest in Kamoa-Kakula to nearly 45%.

In line with the DRC Government’s policy to promote more Local Value Addition (#LVA), the KIK project is underway to produce copper cathode. The electrolysis plant inputs copper anode at 99.7% purity and outputs copper cathode at 99.99%. It is a fully vertically integrated project involving extraction, concentration, smelting and electrolysis. It is scheduled to become operational by June 2026.